Aerospace Component Testing

Aerospace Component Testing

- Pressure Test Benches

Aerospace Pressure Test Benches

Testing systems from Poppe + Potthoff Maschinenbau put fluid systems and components for aerospace applications through tough trials. In service life tests they are subjected to thousands of load cycles. Weak points can thus be identified and eliminated at an early stage. In this way, a level of quality is achieved that meets the highest safety requirements and strengthens confidence in the technology, which further advances the fascination for aerospace.

Stay Cool with Rising Pressure

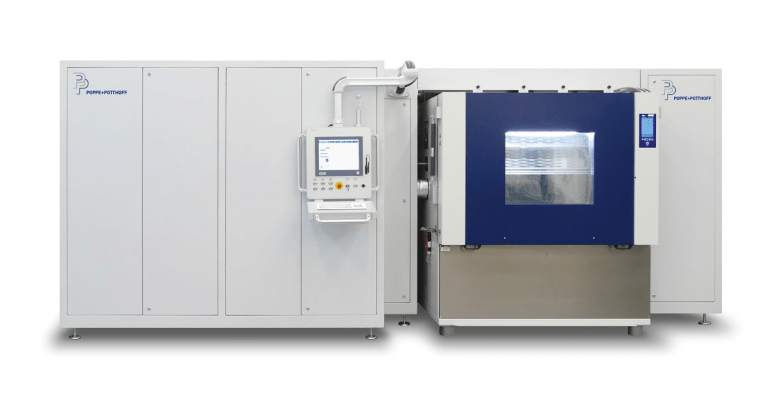

With the PPM pulse test stand, Poppe + Potthoff Maschinenbau offers a powerful system for testing cooling elements for the aerospace industry. The electronics on board produce a lot of heat which has to be dissipated to ensure that the systems function reliably. The pulse test stand is used to simulate a controlled pressure change in different frequencies and pressure ranges. The system consists of two modules. The supply unit houses the pressure intensifiers, cooling and heating units and the control system. The actual testing takes place in a climate chamber in which the test specimens are tested at a media temperature of -40°F (-40°C) to +320°F (+160°C) and varying environmental conditions from -58°F (-50°C) to +320°F (+160°C). Simultaneously, up to four components can be tested independently of each other in the climatic chamber with the PPM 432. The pressure intensifiers are designed differently for this purpose: One generates a pressure of up to 1000 psi (70 bar), two are designed for up to 4000 psi (275 bar) and one for up to 6000 psi (414 bar). Aerospace oil is used as the test medium

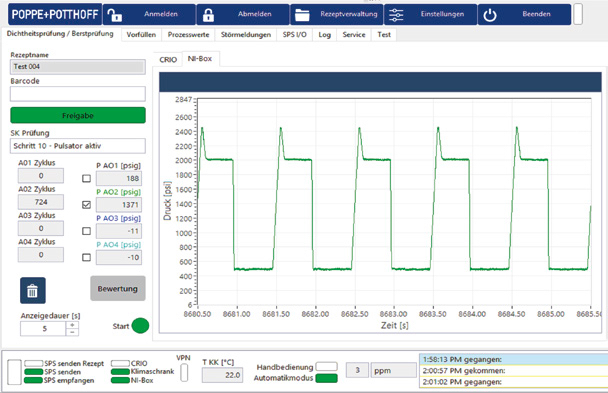

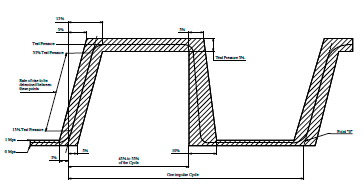

Needle Peak, Sine or Trapezoid Test

The PPM 432 can change the pressure in up to 100 load steps per minute and sets pulses with a frequency of 0.2 Hz to 5 Hz. The test curve is usually controlled with a sinusoidal or trapezoidal curve. But also pressure holding tests and individual pressure curves with 10 points can be performed. Thus, all common test standards, such as ISO, UNI, SAE, ARP or MIL, can be flexibly fulfilled. The test stand is operated via an internal programmable logic controller (PLC) and a panel PC directly at the machine. The integrated LabView software from National Instruments enables efficient data acquisition and visualization. All test procedures and data are automatically stored by the system and can be exported to the network for evaluation. The open software structure allows additional sensors and data to be integrated during the tests. Poppe + Potthoff Maschinenbau adapts each system individually to the specific needs of the customer and also offers numerous testing services, remote maintenance and technicians on site.

Perfomance Data – PPM 432 Pressure Cycle Test Bench

Dynamic test pressure min. 0 psi (0 bar)

Dynamic test pressure max. 1 x 1000 psi (70 bar)

2 x 4000 psi (275 bar)

1 x 6000 psi (414 bar)

Curve shape Sine | Trapezoid | Static

Speciality An individual pressure curve with a maximum of 10 points can also be set

Frequency 0.2 Hz-5 Hz

Load steps 1-100 per minute

Media temperature min. -40°F (-40°C)

Media temperature max. +320°F (+160°C)

Ambient temperature min. -58°F (-50°C)

Ambient temperature max. +320°F (+160°C)

Ambient alteration speed 1.5 K per minute

Test chamber size W x D x H 1500 x 900 x 900 mm

Test medium aerospace oil

Number of test specimens max. 4 (upon customer request)

Flow rate per test specimen 0-4 l per minute

Performable tests Pulse pressure test

Pressure holding test

Dimensions and weight Width: ca. 4808 mm

Depth: ca. 2369 mm

Hight: ca. 2333 mm

Weight: ca. 5000 kg

Global Test Standards

ISO, SAE, UNI, ARP, MIL, ARP

Test Standards for Trapezoid Pressure Curve

ISO 1436 rectangular curve form

IS0 6802 omega – horizontally shifted

ISO 8032 half omega test

ISO S1436

UNI EN ISO 6803 (DIN20024)

UNI EN ISO 6605

UNI 9540 rectangular curve form

UNI 9539 omega test – SQR curve

SAE J343 rectangular curve form

SAE J1405 (opt.) omega test

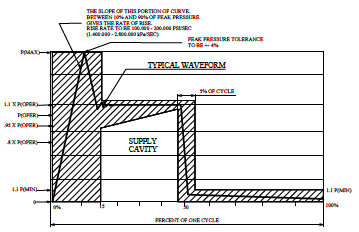

Test Standards for Needle Peaked Curve Shape

ISO 6772 peaked curve shape

ARP 603 peaked curve shape

ARP 1383 peaked curve shape

prEN 2624 peaked curve shape

MIL-A-5503E peaked curve shape

MIL DTL 8788D

MIL DTL 13531

ISO 6772 peaked curve shape