E-Mobility | Automotive Testing

Environmental Simulation | Climate Chambers | Media Tempering

E-Mobility | Automotive Testing

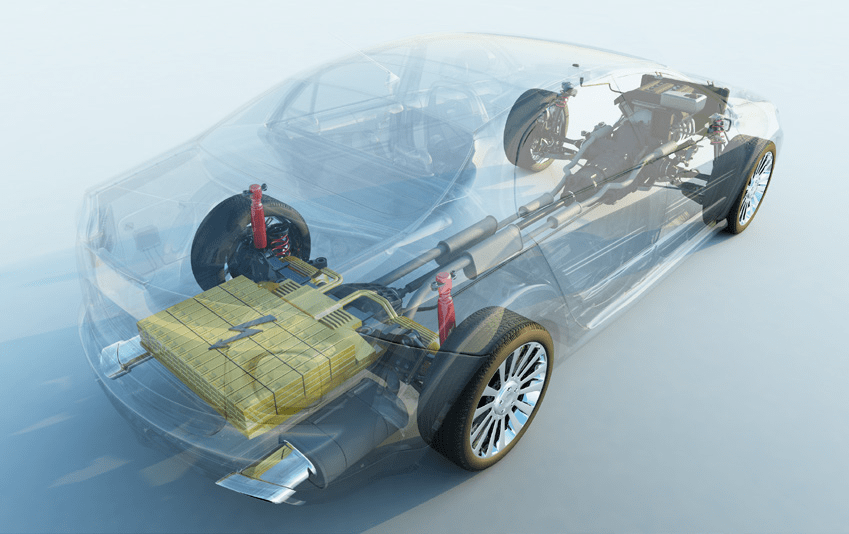

Poppe + Potthoff Maschinenbau GmbH develops and manufactures systems for testing the operation and fatigue strength of components in the automotive sector. Automotive testing is at the core of Poppe + Potthoff.

To demonstrate the quality of media-carrying vehicle components, the drive units (electric motors), valves, cooling and heating systems, hose lines, tubes, pressure vessels and other components are subjected to pressure. Whether for dynamic pressure change tests, static pressure holding tests, flow measurements or classical bursting pressure tests.

Poppe + Potthoff Maschinenbau offers you an individual solution matched to your requirements. In addition to the pressure and lifecycle tests, the test benches from Poppe + Potthoff Maschinenbau provide the possibility to carry out functional tests with live components. Here, the focus is primarily on efficient energy management as well as the performance under changing temperature conditions.

Energy Efficiency in Battery Operation

In addition, Poppe + Potthoff Maschinenbau offers a function test bench for electrical appliances such as cooling and heating units, control valves and pumps. Power consumption and performance are typically tested at alternating temperatures – optionally with a low- or high-voltage power supply to simulate operation via onboard battery and generator or the traction accumulator.

In many EVs, the heating and cooling systems drain the battery and negatively affect the vehicle’s range. Comparison of test results before and after a load test on the pressure cycling test bench can show how power consumption and performance change over the vehicle’s service life. The test object is connected to the power supply (low voltage 0-20VDC/5A) or high voltage (0-600VDC/150A) and the test media circuit. The test medium is circulated at a temperature of between -35°C to +100°C (-31°F to +212°F) and a flow rate of 1-50 l/min. The test can also be carried out in a climatic chamber at -40°C to +140°C (-40°F to +284°F) simulating changing ambient temperatures.

Thermal Management

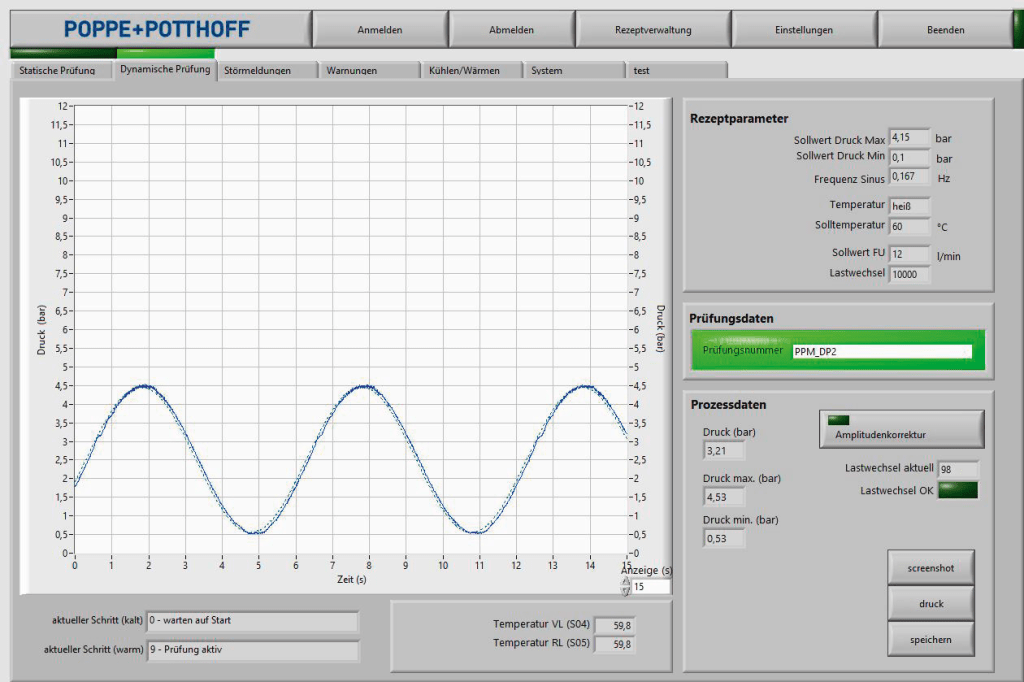

For thermal management in the vehicle, cooling and heating systems are essential. They protect against overheating and ensure comfort. Poppe + Potthoff Maschinenbau developed a special system to simplify and speed up life cycle tests. It simulates driving for the test specimen through freely programmable temperature, volumetric flow rate and pressures changes in a sinusoidal and trapezoidal form.

Mobility calls for reliable cooling and heating systems. They help people and machines – whether electric or combustion engines – adapt to varying environmental conditions on land, water and in the air. In the process, climate systems and all their components must permanently stand up to high load changes. Instead of expensively testing the durability in real operation, manufacturers can now try out their components with the help of the pressure change test bench of Poppe + Potthoff Maschinenbau in an early stage of development, and can do so flexibly and economically in fast motion.

Cooling and Heating – Automotive Testing

In a typical test, the component is inserted into the test chamber of the pressure cycling test bench. This can be an auxiliary heater for an electric car or valves, hoses and other hollow bodies that need to withstand more than 100,000 load changes over the lifetime of the vehicle (up to 15 years). The test medium is a water-glycol mixture or pure glycol (for example Glysantin G40, G44, G48). The cooling circuit is tested at -40°C to +20°C (-40°F to +68°F) while a heating circuit is tested in temperatures from +20°C to +140°C (68°F to 284°F). A specially developed closed test media circuit uses pressure to prevent formation of alcoholic vapors ( explosion risk). A system can also be analyzed in a climate chamber.

The flow rate of the test medium can vary from 1-50 l/min at a pressure of 0.2-12 bar or higher. The load changes are freely programmable with sinusoidal or trapezoidal rise at a test frequency of 0.2-2 Hz or faster. The test stand can be used for complete systems, assemblies and components made of various plastics, metals and sealants. Weak points in the material combination – for example around a weld seam – can be sounded out and optimized early in the development process as well as during production.

The pressure cycling test bench from Poppe + Potthoff Maschinenbau tests climate-control components at –40 to +140 degrees Celsius. Temperature, volume flow and pressure changes can be freely programmed in sinusoidal and trapezoidal form at a test frequency of e.g. 0.2 to 2 Hz and enable fast and economical testing.

Time Lapse for Long-Term Tests

A long-term test usually takes 20-30 days, depending on the frequency of the load changes. The temperature and volume flow of the test medium as well as the ambient temperature (if the test takes place in the climatic chamber) vary according to the test specification. The temperature at the inlet and outlet of the test object is measured continuously, as well as the flow rate, pressure and pressure drop, and current and voltage (both in the high and low range). The focus is on the thermal and electrical performance of the heating and cooling unit under varying environmental conditions. Thermal sensors can be mounted on the product to indicate during the test when energy is lost (thermal bridges) or when the component becomes very hot (and thus presents a fire hazard).

Safe and Easy to Use Test Machines

Poppe + Potthoff Maschinenbau test systems are easy to operate and extremely safe. The test chamber consists of welded stainless steel and a high-strength polycarbonate safety window. Any test sequences created on the PC can simply be called up manually via coded recipe management or by a handheld scanner. The integrated LabView software from National Instruments enables efficient data acquisition and visualization. Test procedures and data are automatically stored on the system and can be exported to the network for evaluation. The open software structure makes it possible to integrate additional sensors and data during testing. Poppe + Potthoff Group can provide numerous testing services, remote maintenance and on-site technicians, if necessary.

Key Features of the displayed Test Bench:

- Temperature ambient: -40°C to +150°C with rate of change 3,5 K/min

- Temperature fluid: -40°C to +140°C

- Test chamber: with Ex protection for pressure test with coolant (ATEX)

- Size of test chamber: 1,500 x 1,000 x 1,000 mm (W x H x D)

- Flow rate coolant: ‘ 0,5 l/min up to 30 l/min adjustable

- Test pressure: dynamic 0,2 to 6 bar with sinus- and trapezoidal curve

- Frequency: up to 2 Hz (further frequencies upon request)

- Pressure drop test: up to 1,000 mbar

- Static pressure test: up to 20 bar with compressed air and adjustable pressure increase

- Leak rate test: 0,5 cm3/min

- Vacuum testing: Pressure variation between atmosphere and 18 mbar